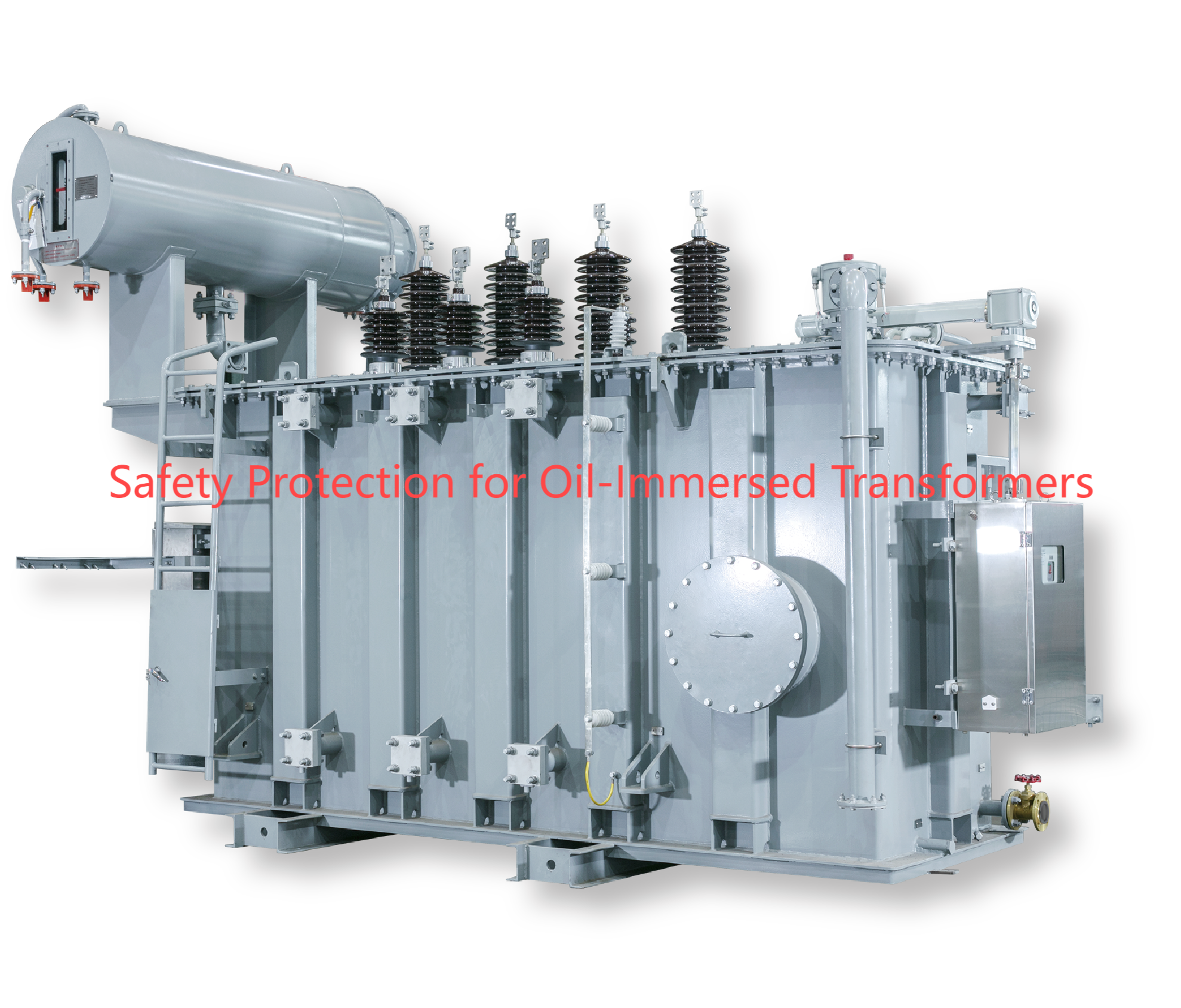

This section discusses security measures and the considerations that apply to oilimmersed transformers, which includes distribution transformers and those that are filled with oil.It emphasizes the importance of maintaining appropriate oil levels, and also ensuring that there is adequate insulation to avoid dangers.

Introduction

1.Understanding OilImmersed Transformers

2.Comparing OilImmersed and Dry Type Transformers

3.Fire Safety Measures

4.Preventing Oil Leakage and Managing Oil Levels

5.Importance of Maintaining Oil Quality

Conclusion

Introduction

Oilimmersed transformers are essential elements of the power distribution system.They are efficient in cooling and insulation, vital to ensure safe and reliable operation of high voltage systems.This article examines the main aspects of oilimmersed transformers. precautions to avoid risks, and also a comparison with dry type transformers.

1.Understanding OilImmersed Transformers

Aoilimmersed transformeris constructed to work using insulating oils that cool internal components and supplies insulation for electrical power.Oilfilled transformers is common in a variety of applications, especially when there is a high voltage.This kind of transformer usually comprises of windings that are submerged in oil. This helps to maintain the optimaltemperature of the oiland allows for effective heat loss.

Key Components

WindingsThe windings are vital for the transformation of voltage and are specifically designed to take on large electrical loads.They could be made of aluminum or copper with copper providing greater conductivity, but with a higher price.

Insulating oilIt serves double purpose of cooling the transformer, and also building electrical insulation in order to avoid leakage and short circuits.The most common types of insulating oil include synthetic esters and mineral oils and synthetic esters, the latter of which provides greater environmental protection.

TankIt holds oil in it and shields the interior components against environmental influences.Tanks are generally constructed from steel, and are made to withstand pressures externally and impact.

Comparing OilImmersed and Dry Type Transformers

Although oilimmersed transformers are commonly employed,dry type transformersare getting more and more popular in certain areas due to their security characteristics.Heres an example Feature OilImmersed Transformer Dry Type Transformer Cooling Method Oilinfused immersion Air cooling Fire Safety It requires additional systems Generally speaking, safer Maintenance More frequent checkups are needed. Maintenance less frequent Voltage Levels Ideal for high voltage Limited to voltages lower Oil Leakage Risk Yes No For example Dry type transformers can be often employed in indoor environments, like commercial buildings and hospitals in which security and space are important.On the other hand oilimmersed transformers are commonly used in power plants and substations that have high voltage levels and bigger capacities are needed.

Fire Safety Measures

Safety of fire is the primary issue when it comes to transformers with oil in the pipeline.Because of the flammability, fuel demands strict fire safety protocols.Here are some important steps to ensure safety from fire

Routine InspectionsPerform regular checks to check for indications ofleakage of oil.Take action immediately to avoid the risk of fire and environmental hazards.

Fixed Spray SystemsInstall fixed water spray systems that can quickly eliminate any fires that might develop.These auxiliary systems will effectively cool the transformer, and reduce damage to the transformer.

Temperature MonitoringContinuously monitorthe temperature of oilas well asVoltagelevels.Sensors can detect overheating which could signal potential problems.

Security Training for FireEnsure that all employees are properly trained in fire safety procedures, such as how to handle emergencies involving transformers.Regular training sessions can help prepare employees for emergencies.

Containment SystemUse containment devices around oilimmersed transformers in order to prevent leaks and spills from spreading. This could create additional fire hazards.This could be in the form of Bunded areas, and secondary tank containment systems.

Preventing Oil Leakage and Managing Oil Levels

Leakage of oilis among the main concerns for transformers that are filled with oil.Regular checks for maintenance are necessary to keep track of theoil leveland identify leaks in the early stages.If there is a leak it is essential to immediately take action to stop it from recurring and prevent any further problems.

Tips for Managing Oil Levels

Routine ChecksRoutinely monitor the levels of oil in the tank of transformers.Maintaining the proper oil level will ensure optimal insulation and cooling.

Leak Detection SystemsInstall leak detection systems that notify maintenance staff of leaks in realtime which allows for rapid intervention.These systems could include alarms that are visual and also auto shutoff valves.