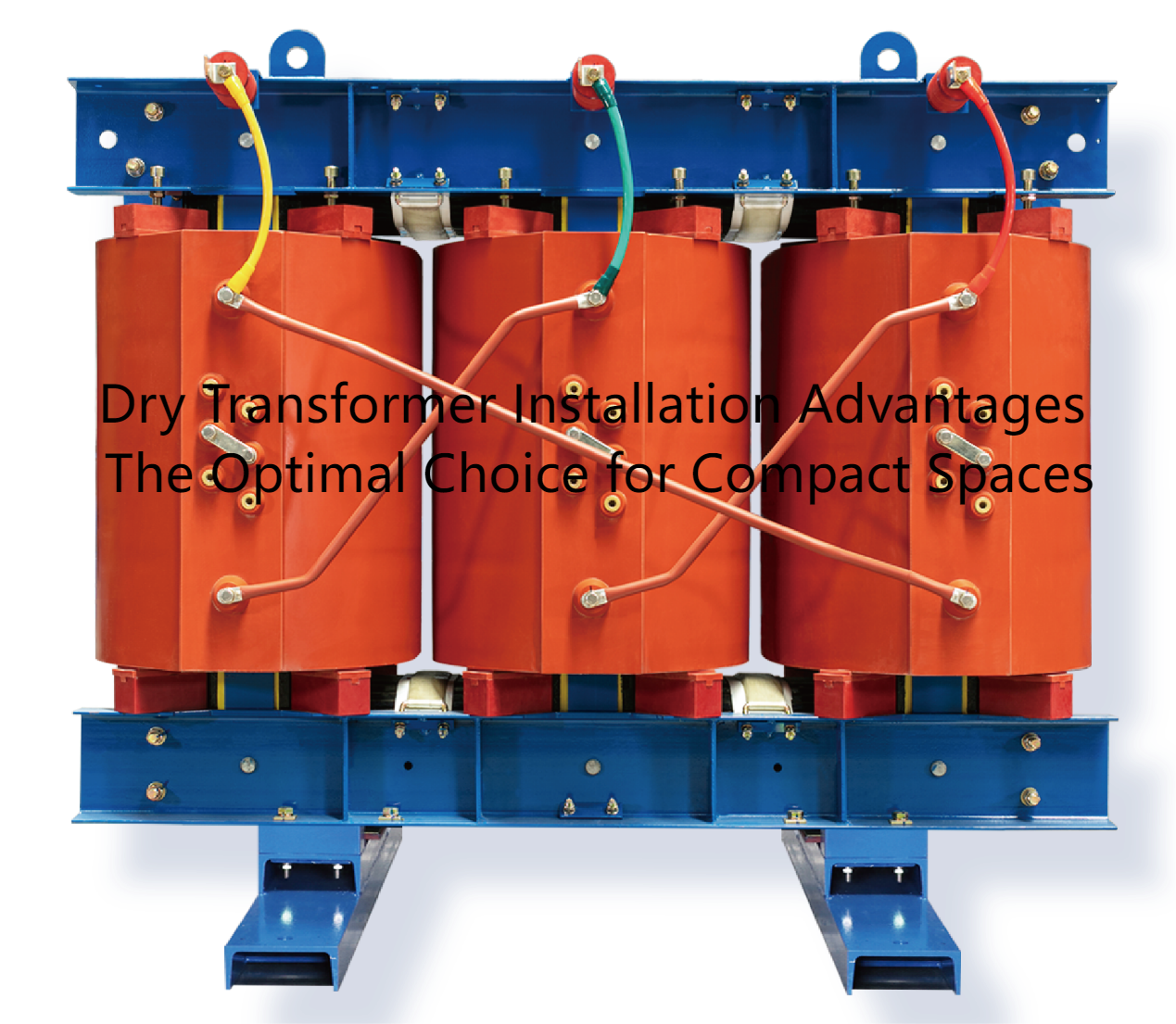

This passage serves as a guide on the benefits of drytype transformers, particularly in compact settings and specialized industry applications. Unlike oilfilled transformers, drytype transformers provide efficient, safe, and reliable operation without requiring flammable materials. They offer an ideal solution for electrical systems, ensuring consistent voltage levels in confined environments. With easy installation and high efficiency, drytype transformers are widely valued in the industry for their ability to enhance safety and maintain longterm, lowmaintenance operation.

Introduction

1. Enhanced Safety in Compact Environments

2. Environmentally Friendly and Low Maintenance

3. Compact and SpaceEfficient Design

4. Resilience and Durability

5. Noise Reduction Benefits

6. CostEffectiveness Over Time

7. Ease of Installation and Mobility

Introduction

When it comes to energy distribution, drytype transformers are increasingly being recognized for their distinct advantages, especially in areas where space is limited. Unlike their oilcooled counterparts, dry transformers offer a safe, efficient, and compact solution ideal for both commercial and industrial applications. This article explores the key benefits of installing drytype transformers, focusing on why theyre an excellent choice for confined spaces.

1. Enhanced Safety in Compact Environments

One of the most notable advantages of drytype transformers is the high level of safety they offer. Since they dont require oil for cooling, they eliminate the risk of oil leaks and fire hazards, making them suitable for densely populated areas or confined spaces. In areas like office buildings, shopping malls, and hospitals, safety is paramount, and dry transformers provide peace of mind with their fireresistant design. Their lack of flammable liquids also means that there are fewer safety protocols required, simplifying installation and maintenance in restricted environments.

2. Environmentally Friendly and Low Maintenance

Drytype transformers use air as their cooling medium, making them far more ecofriendly than oilcooled transformers. This airbased cooling system reduces the need for regular monitoring and maintenance, as there is no risk of coolant leakage or contamination. For facilities prioritizing sustainability, dry transformers align perfectly with environmental goals, as they emit zero greenhouse gases and are fully recyclable. Their minimal maintenance requirements also lead to cost savings over time, as they do not need regular oil changes or coolant replacements.

3. Compact and SpaceEfficient Design

Dry transformers are renowned for their compact design, making them ideal for installations where space is a premium. The lack of an oil tank and associated cooling mechanisms allows for a smaller footprint, which is particularly beneficial in urban settings or within buildings with limited floor space. These transformers can even be installed close to walls or other equipment, maximizing every inch of available space. In addition, they can be mounted on walls or ceilings, further optimizing floor space.

This flexibility in installation also makes drytype transformers highly versatile for retrofit projects or facilities with unique layout requirements. Their compact design allows them to be easily integrated into existing systems without major structural changes, making them a costeffective choice for modernization projects.

4. Resilience and Durability

Drytype transformers are engineered to withstand harsh environments, making them ideal for various applications, from industrial plants to highrise buildings. They are resistant to chemical pollutants, moisture, and dust, which can significantly extend their lifespan compared to oilcooled transformers. For facilities with challenging environmental conditions, dry transformers offer reliable performance with less risk of malfunction due to external factors.

Moreover, because they dont contain oil, dry transformers are far less sensitive to temperature fluctuations, which makes them suitable for extreme climates. This robustness ensures that they operate efficiently in both high and low temperatures without the risk of coolant freezing or overheating, which can be critical in regions with unpredictable weather patterns.

5. Noise Reduction Benefits

Drytype transformers are typically quieter than oilcooled transformers, a feature that can be especially important in buildings or areas where noise control is essential, such as residential complexes, hospitals, and educational institutions. They operate with minimal vibration and noise, making them less disruptive to daily activities. This noise reduction is particularly valuable in compact spaces, where sound may travel and amplify more easily, affecting the comfort of occupants.

6. CostEffectiveness Over Time

While the initial cost of a drytype transformer may be slightly higher than that of an oilcooled transformer, the longterm savings can be significant. Their low maintenance requirements and long lifespan contribute to reduced operating expenses. Additionally, the lower risk of fire and reduced need for safety measures translate to lower insurance premiums and less frequent regulatory inspections. Over time, these factors make dry transformers a costeffective choice for many facilities.

7. Ease of Installation and Mobility

The installation process for drytype transformers is relatively straightforward, as they dont require oil containment systems or extensive cooling infrastructure. This simplicity makes them easier to transport and install, even in hardtoreach areas. For sites with complex layouts or restricted access, such as underground facilities or skyscrapers, dry transformers offer the added benefit of flexibility in installation.

Conclusion Dry Transformers as the Top Choice for Confined Spaces

In summary, drytype transformers are an excellent choice for installations where space, safety, and environmental considerations are critical. Their compact size, reduced maintenance, and resilience make them particularly suited for urban and confined spaces. For any facility prioritizing sustainability and safety, dry transformers provide a reliable and longlasting solution thats both costeffective and easy to maintain.

By choosing a drytype transformer, facilities can benefit from enhanced safety, minimized environmental impact, and efficient energy distribution in even the most restricted environments.